Chainsaw Sharpening and Chainsharps

- Paying chainsaw shop to sharpen on grinder

- Freehand filing--with and without guides

- Clamp on filing jig

- Chainsharps by Pferd

Grinder:

Pro: Achieves uniform sharpness with little effort

Con: Costs $5 per chain (at your sharpener guy)

Con: Grinds all teeth to the dimensions of the smallest tooth--unnecessary

Con: Heats each tooth to the point of discoloration and losing temper--chips more easily

Con: Sharpener guy says "I'll get the rakers (depth gauges) every 2nd or 3rd sharpening"

Freehand:

Pro: Simple

Con: Must develop smooth, consistent stroke (guides help here)

Con: Rakers/depth gauges must be addressed with separate file and guide

Clamp-on Filing Jig:

Pro: Very consistent stroke--good uniformity

Con: Fiddle factor for clamping on jig

Con: Must address rakers/depth gauges with separate file and guide

Chainsharps:

Con: Must develop consistent stroke--alignment guides help

Pro: Simple

Pro: Maintains proper depth gauge WITH EVERY SHARPENING!

It's this last point that was the kicker for us! The Pferd Chainsharps keep the depth gauge at the perfect height for the amount of wear on the cutter tooth. That way the size of the chip is always "just right".

Chain Teeth - Cutters and Rakers

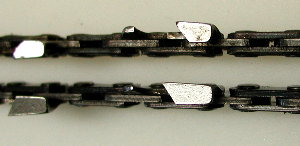

Here we look at well-worn and new chain

Notice on the new chain how long the cutter tooth is. Also note the bump of metal in the lower part of the gullet. That bump appears to be a remnant from the manufacturing process. Unfortunately, regardless of the sharpening method used, that metal must be removed (by the proper size file) in your initial sharpenings. As the tooth gets "trained", the round file sits at the proper depth and strikes the gullet and the top cutter at the proper depth and angle.

I find that, barring any other problems with a dull tooth, it takes about 10 strokes per tooth on the first sharpening or so. Then, once the chain is "trained", it only takes about 5 strokes per tooth to dress them up.

Well-worn chains have four attributes--two good and two (potentially) bad. First, a well-worn chain has been through enough heating and cooling cycles that it won't stretch much anymore. That means fewer adjustments for chain tension. Next, you'll notice that a well-worn chain cuts WELL! The distance between the raker and the top cutter is increasing and the depth gauge is having less effect. As a result, the tooth cuts lots of wood all the time. You'll seem to rip through logs. One downside to a well-worn chain also stems from this increasing gap between the raker and the top cutter. You'll notice much more kickback and chatter when trying to bore cut. Kickback is dangerous! So, if it's annoying, throw away your old chain and put on a new one. Also, as your chain becomes well-worn, the cutter tooth becomes very small and may break-off or chip. That would be one signal it's time to put on a new chain.

Buy TWO Chainsharps!

Here at Richwood Timber we have some tips to share with you:

- Buy a six-pack of RED Sharpie markers. Mark your starting tooth with the

marker and it will be obvious when you've worked your way around the chain. Black

markers don't stand out enough. Keep a red marker with your Chainsharps.

- Buy two Chainsharps! Chainsharps come with instructions on how to flip the

round file and the flat file around from "left" to "right" configuration. The only

problem is, since one file fits in the top and the other in the bottom, it is EASY to

drop one of the files in the snow during the reconfiguration. The EASY and BETTER

solution is to buy TWO Chainsharps and leave one set-up for "right" and the other

for "left". Mark them clearly "L" and "R"! At about $17/each, it's a small price

to pay to have two and avoid having to reconfigure the Chainsharps.

- Have ample stock of round files on hand. At about a buck apiece, pitch a worn round file and pop in a fresh one. You'll be more efficient.

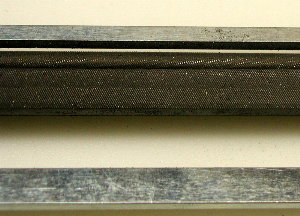

Files

Chainsharps come with either a 7/32" or 3/16" round file (depending on what you order). Plus, they come with a flat bar file that works on the rakers. This flat bar file only files in one direction. The file has two sides so you get two sides to wear out. I went two seasons before I changed the flat bar files (about 100+ sharpenings). Buy a spare set of these flat bar files and have them ready to go.

Round files: I get about 7-8 sharpenings when I'm "training" or "breaking-in" a new chain. This means 10 to 12 strokes per tooth. Once I have a trained chain, I get 10 or more sharpenings out of the round files because I'm only doing about 5 strokes per tooth to dress them up. Above all, I don't hesitate to pull a worn set of round files (and send them to the metal recycling bin). At about a buck apiece, I'm much more productive with fresh round files. A new round file just feels GOOD!

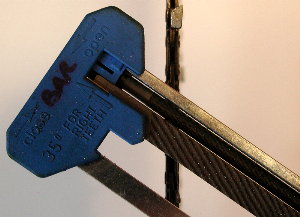

I've noticed a difference between brands of round files. I tend to use 7/32" round files. While I like most Woodsman Pro products, I've noticed that their round files aren't particularly straight (true). Notice the daylight gap that varies while I roll the Woodsman Pro round file in position. These microns of difference surely contribute to a lack of uniformity (of unknown consequence). I've noticed that the Pferd brand round files tend to be more true and straight.

Here is how much variation in one spin of a Woodsman Pro file. I tend to see less variation in one spin of a Pferd file.

Excellent Resources at Pferd Website

Literature/Video Page --Look for two things near the bottom of the page:

Chainsaw Files & Accessories

PFERD Chain Sharp® Video

Richwood Timber LLC

richwoodtimberllc (at) w9fz.com